ConcretePilot

From job batching to panel positioning to management reporting, you’re in command! With an intuitive operator interface, projecting panel templates is as easy as opening e-mail.

The software for concrete applications

Your builders will be spending less time jigging setups and more time rolling finished parts out the shipping door. Immediately. Period.

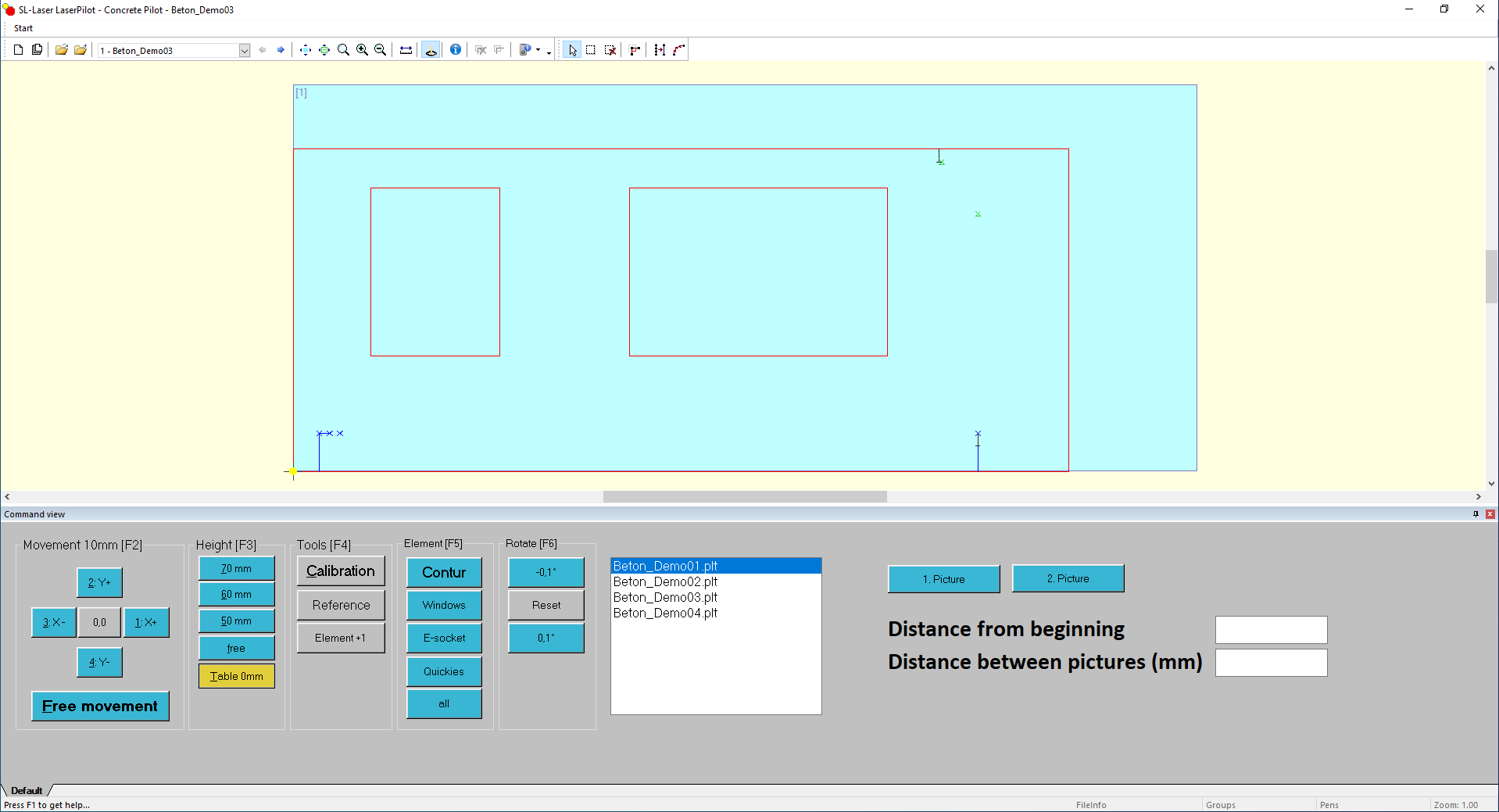

Working with ConcretePilot

The ConcretePilot menu and control areas are completely configurable to allow the user to create an interface that can be easily learned and operated by plant-floor personel. The on-screen control buttons can be custom designed and triggered at the table with remote controls.

Every SL Laser Projection System is custom-tailored to your building process by a SL Laser factory-trained technician. This system can be easily modified by anyone with basic software skills using a well documented command set of control options. The system is password-protected to prevent tampering by unauthorized personel.

PC Requirements:

Windows Operating System (Windows 7 or newer) with a pointing device or touchscreen and an available Serial or USB port.

Definition:

Component control– Break up your drawings into logical projection sequences – project components in order to drive your assembly process. Use the remote control to quickly scroll place your components to the laser light and you’re off to the next setup. Fast. Simple.

Positioning – You can move, flip, mirror, and even rotate panels to get the optimum position on your table.

Group

Create a group of drawings to coordinate the data of the coming shift. All the workers then have to do is press “Next part”.

Reports

Which shift takes the most time to form? Which operation takes the longest? Which team produces the most profit. Find out with ConcretePilot Reports software.

Do you have

any questions?

Contact us.