Laser Projektionssysteme in der Steinindustrie

In der Steinindustrie finden sich besonders viele Anwendungsbereiche für die Projektionssysteme von SL Laser. In dieser hart umkämpften Branche ist eine Optimierung der Präzision und die gesteigerte Effizienz bei der Produktion willkommen. Allein die Verkürzung der aufwendigen Rüstzeiten ist schon ein deutlicher Gewinn. Der Einsatz läuft von der ersten Vermessung über den Zuschnitt bis zur Verarbeitung der Aufträge auch aus der gleichen Platte. Mit den speziell entwickelten Programmen für unsere Produkte werden 3D-Vermessungen möglich, CAD-Daten übernommen, umgerechnet und alle Arbeitsschritte seriell oder parallel vorgegeben.

Vorteile für die Steinindustrie

Bei CNC-Zentren erreicht man eine Verkürzung der Rüstzeiten und beschleunigte Durchgänge mit reduziertem Ausschuss.

Beim Nesting schneller Schnitt verschiedener Aufträge aus derselben Platte, Schablonen werden durch Projektion ersetzt.

Mit der Berechnung vereinfacht sich die Positionierung und Bearbeitung schwerer Platten ohne physische Verschiebung.

LaserPilot-Software ermöglicht parallele Arbeitsschritte und zeigt sich dabei kompatibel mit den meisten CAD-Programmen.

Typische Einsatzbereiche unserer Laser in der Steinbearbeitung

Bei der Arbeit in CNC-Bearbeitungszentren, beim Vermessen von Treppen oder Mauern und sogar beim Verlegen von Stein-Inlays werden Kosten gespart und die Qualität gesteigert. Kein Unternehmen, das die SL Laser Produkte testet, will danach auf diese Vorteile verzichten. Im CNC Bearbeitungszentrum beschleunigen sich die Durchgänge deutlich, bei drastisch reduziertem Ausschuss. Beim Zuschnitt und der verschiebungsfreien Bearbeitung von Steinplatten wird Arbeitszeit und Material gespart. Beim Aufmaß und der ebenso möglichen Projektion der Daten im Wand- oder Treppenbau wird der ProCollector L auch mobil eingesetzt.

Weitere Informationen zur Anwendung in der Steinindustrie

Laserprojektion in CNC-Bearbeitungszentren

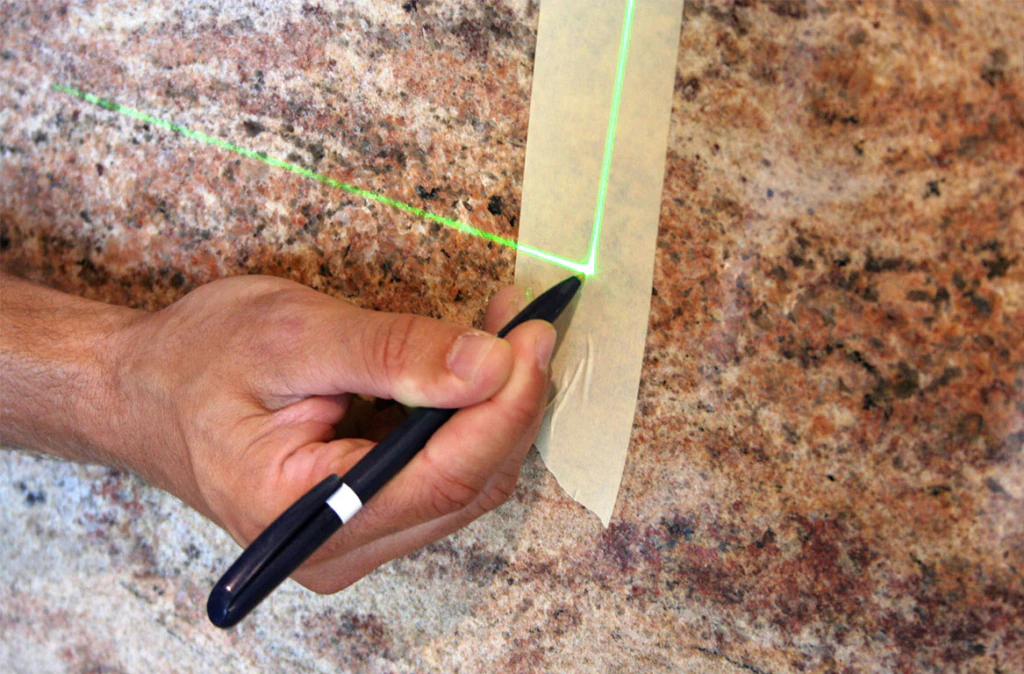

Die Laserprojektion reduziert die Einrüstzeit drastisch. Der ProDirector 7 arbeitet entweder direkt integriert in die Steuerkonsole der CNC-Oberfräse oder konvertiert seine Daten aus dem CAD-Programm. Mit der präzisen Positionierung von Werkstücken und Saugern werden zeitraubende Kontrollfahrten mit aufgesetztem Werkzeug überflüssig. Die teure Beschädigung von Saugern ist ausgeschlossen.

Der ProDirector 7 projiziert die Zeichnung mit allen Positionen und Konturen im Maßstab 1:1 auf der Oberfläche. Der grüne Laserstrahl ist auf dem Rohling oder dem Tisch gut zu erkennen und erleichtert die Arbeit.

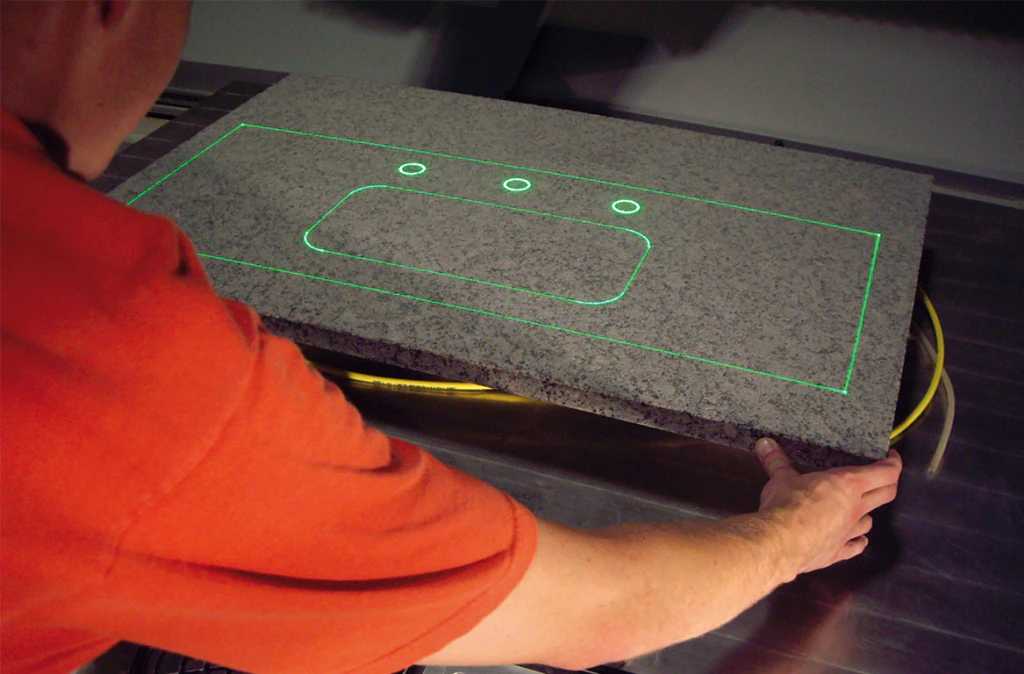

Der ProDirector 7 beim Nesting

Erledigen Sie unterschiedliche Aufträge aus der gleichen Platte im Handumdrehen. Die Projektion der Laserstrahlen ersetzt die kostspieligen Schablonen. Der Projektor projiziert die Kontur aus der ersten CAD-Zeichnung auf die Platte. Jetzt wird eine weitere Zeichnung mit der entsprechenden Kontur hinzugefügt. Mit der Maus drehen und verschieben Sie auf dem Bildschirm diese zwei oder mehrere Konturen so zueinander, dass die ideale Aufteilung entsteht.

Der ProDirector projiziert die Ergebnisse auf die Platte. Sie erreichen Ihr Arbeitsziel mit dem geringsten Arbeits- und Zeitaufwand, ohne Material- und Werkzeugeinsatz.

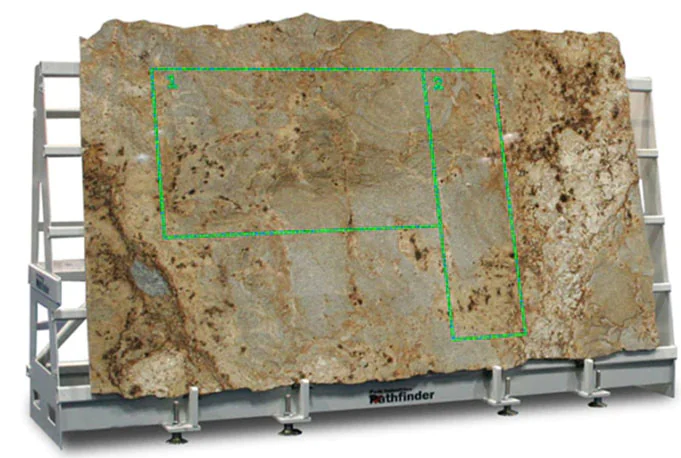

Laserprojektion für schwere Granitplatten

Nutzen Sie die Flexibilität des ProDirector 7 in Bezug auf Positionsänderungen. Die Konturen der Zeichnungen werden für die verschiedenen Arbeitsschritte einfach so umgerechnet, dass die schweren Granitplatten nicht mehr bewegt werden müssen. Die nur auf der Zeichnung nötige Verschiebung wird erfasst, umgerechnet und die Veränderung wird mitsamt den entsprechend angepassten Daten direkt an die Steuerung weitergegeben.

Dabei unterstützt Sie die LaserPilot Software wie bei vielen anderen Aufgaben. Speziell auch für solche Arbeitsschritte entwickelt, ist diese Software kompatibel mit den meisten CAD-Programmen.