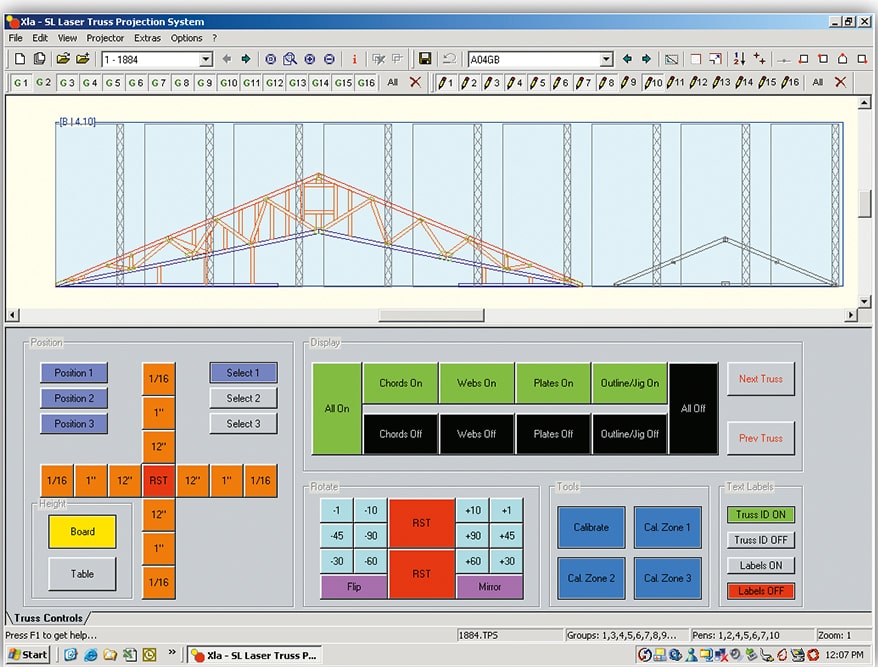

Laserprojektion für Holzfertigteile

Das gesamte Angebot von SL Laser wird weltweit bei der Herstellung und Bearbeitung von Holzfertigteilen eingesetzt. Aufmaßsysteme zur Messung z.B. von Treppen im Innenausbau sind ebenso gefragt wie die Positionierlaser zur Ausrichtung von Werkstücken. Den Löwenanteil übernimmt jedoch der ProDirector 7 mit seinen Varianten für mittlere und große Distanzen. Je nach Größe von Werkhalle und Bauteilen wird der Laserprojektor fest unter der Decke montiert, fährt auf einem Schienensystem oder ist als parallel arbeitendes Verbundsystem installiert. Er projiziert softwaregesteuert sämtliche benötigten Vorgaben und minimiert dabei die Fehlerrate und den Ausschuss.

Vorteile für die Holzbranche

Die Konstruktion z.B. von Einbauteilen wird durch das Zusammenspiel von ProCollector und CAD-System beschleunigt.

In der Fertigung optimiert der ProDirector 7 mit präzisen Vorgaben für Maschinen und Werker die Arbeitsabläufe und Ergebnisse

In der Leimbinderherstellung zeigt die Laserprojektion parallel Positionen für Pressböcke und Formteile an: erhöhte Effizienz.

Der ProDirector reduziert die Rüstzeiten um bis zu 70% und optimiert wiederholte Tätigkeiten durch programmierte Abläufe.

Typische Einsatzbereiche für ProCollector und ProDirector 7 bei der Arbeit an Holzfertigteilen

Schon bei der Planung der Konstruktion für Holzfertigteile kann der ProCollector als Aufmaßsystem wertvolle Dienste leisten. Die erhobenen Daten werden in das CAD-System für die spätere Projektion übertragen und umgerechnet. Der exakte Zuschnitt des Holzes wird mit der Projektion der Rahmen und Umrisse zur Feinjustierung vorbereitet. Beim Einsatz von CNC-Fräsen, Sägen und Hobelmaschinen gibt der ProDirector 7 alle wichtigen Markierungen vor, einschließlich der Positionen für Sauger und Werkzeuge. Die Qualitätskontrolle und Endprüfung für die Fertigteile wird mit dem Laserprojektor erheblich verkürzt und erleichtert.

Weitere Informationen zur Anwendung im Bereich der Holzfertigteile

Die Laserprojektion im Holzrahmenbau

Die Software SL LaserPilot arbeitet mit dem CAD-System zusammen und liefert alle erforderlichen Zeichnungen an den ProDirector. Die projizierten Laserlinien geben millimetergenaue Vorlagen für Nagel- und Schraubenreihen, zeigen Abstände oder Aussparungen. Im Verbundsystem auf langen Tischen kann die Arbeit für Holzständer, Einbauteile und Ausschnitte parallel erfolgen.

Änderungen und neue Zeichnungen werden nach Bedarf eingespielt, oder die Bilder werden gespiegelt, repositioniert und auf unterschiedlichen Höhen projiziert. Der 1:1 Faktor der Projektion gibt die nötige Sicherheit für eine exakte Arbeit.

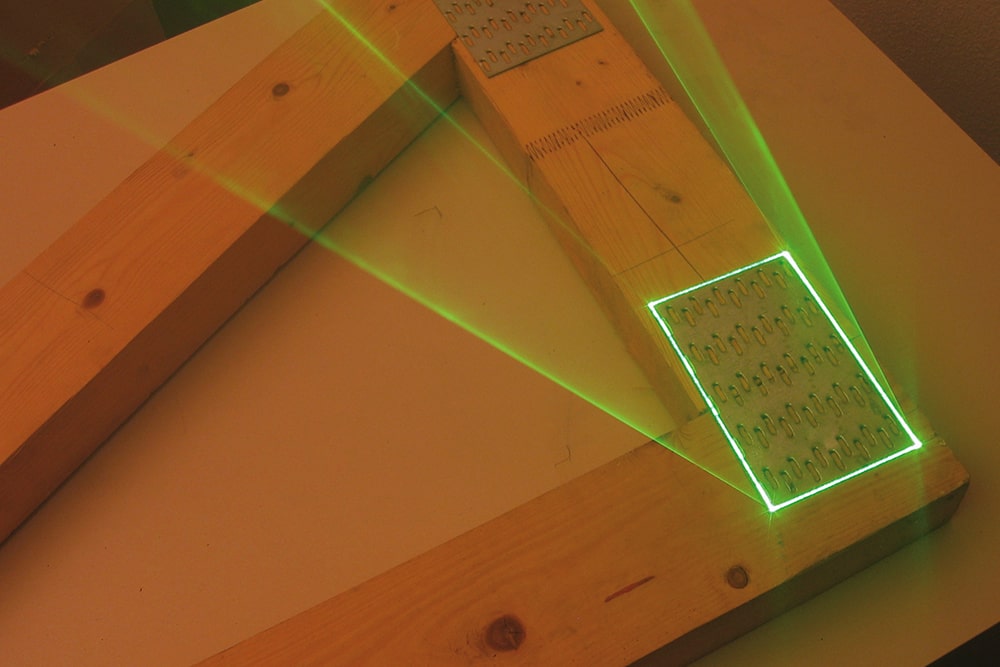

Laserprojektion für Leimbinder

Für Leimbinder wird im Verbundsystem gleichzeitig die Position der Pressböcke und die Form und Ausrichtung der Formteile projiziert. Dabei wird der Projektor in Gruppen oder verfahrbar genutzt. Der Projektor fährt definierte Positionen an und projiziert den jeweiligen Ausschnitt der Zeichnung im Maßstab 1:1.

Wenn der fertige Leimbinder in der CNC-Anlage weiter bearbeitet werden soll, wird seine Kontur abgebildet und per Software so verschoben, dass sie exakt auf die neue Position passt. Mit Übermittlung der Daten an die Maschinensteuerung wird mit minimaler Zeitverzögerung weitergearbeitet.

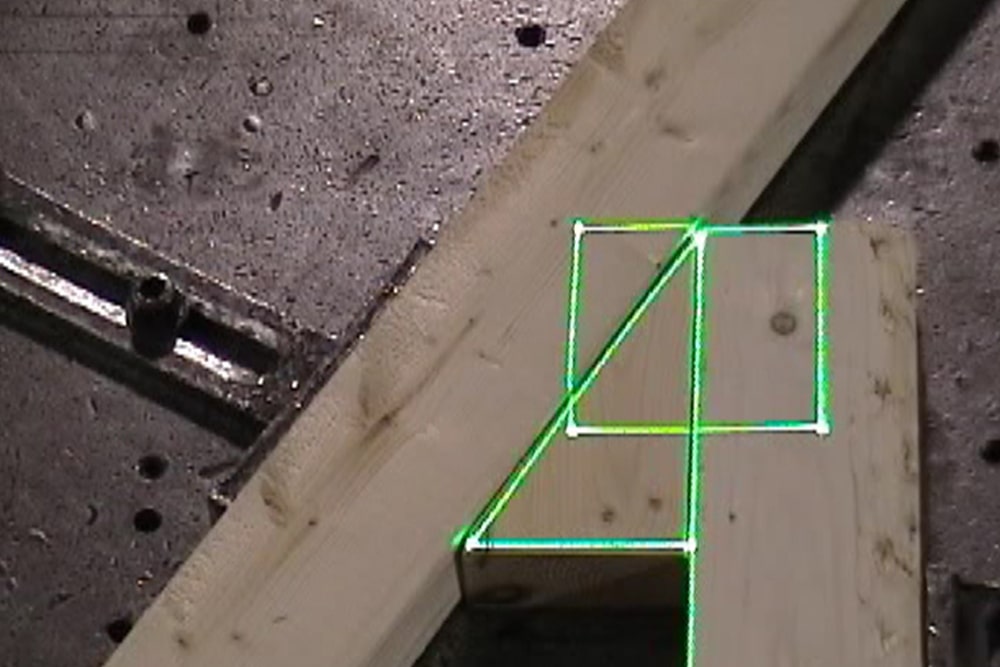

Laserprojektion für Nagelbinder

Die Projektion der jeweiligen Arbeitsphase optimiert auch den Zusammenbau z.B. eines Dachstuhls. Jeder unterschiedliche Rüstzustand wird ohne Schablonen in Sekunden durch das LaserPilot-Programm an den ProDirector weitergereicht, der alle Positionen und Umrisse anzeigt. Die komplette Kontur des Nagelbinders, die Position der Nagelplatten und Anschläge werden abgebildet.

Das erspart bis zu 70% der Rüstzeiten. Dazu kommt noch eine wesentliche Erweiterung der Software. Oft wiederholte Tätigkeiten lassen sich ohne viel Aufwand einprogrammieren und erlauben den sofortigen Abruf bei der Arbeit.