Laserprojektion in der Flugzeugindustrie und im Bootsbau

SL Laser hat sich bei den führenden Herstellern für Luft-und Raumfahrt in Europa als der Anbieter Nummer eins für die Arbeit mit der Laserprojektion etabliert. Zum einen werden die Präzision, Zuverlässigkeit und die leichte Bedienbarkeit der Laserprojektoren geschätzt. Zum anderen punkten die spezifischen Anpassungen bei der Software und den Applikationen, die wir auf Wunsch der Auftraggeber vornehmen. Ähnliches gilt für den Bootsbau. Darüber hinaus sind es hier aber die Aufmaßsysteme, die die Erhebung der nötigen Messdaten auch in engen und gekrümmten Räumen vereinfachen.

Vorteile für die Luftfahrtindustrie und den Bootsbau

Die präzise Projektion reduziert im Flugzeugbau Fehler bei der Montage und vereinfacht die Qualitätssicherung erheblich.

Im Bootsbau ermöglicht der ProDirector mit der Projektion das fehlerfreie Auflegen und Befestigen von Materiallagen.

Im Flugzeugbau entfallen die fehleranfälligen Übertragungen mit Schablonen und ermöglichen eine direkte 1:1 Projektion.

Der ProCollector L revolutioniert das Vermessen im Bootsbau. Er erfasst präzise 3D-Koordinaten auch in schwierigen Räumen.

Passende Produkte für Flugzeug- und Bootsbau

Typische Einsatzbereiche unserer Laser beim Flugzeugbau und im Bootsbau

Im Flugzeugbau werden SL Laserprojektoren ebenso bei Verbundwerkstoffen wie in der Montage eingesetzt. Hier muss eine große Anzahl von Haltern, Klammern, Schrauben und Schaltern mit höchster Genauigkeit gebohrt und montiert werden. Geradezu elegant ist der Einsatz der Projektion bei der Qualitätssicherung, die übergangslos im nächsten Arbeitsschritt erfolgen kann. Im Bootsbau ermöglicht die Anzeige und genaue Projektion der einzelnen Lagen, ihrer Geometrie und der Abmessungen ein fehlerfreies Auflegen und Befestigen. Die kompakte Bauweise des ProDirector 7 erlaubt in engen Räumlichkeiten die Anzeige von Konturen und Montageteilen.

Weitere Informationen zur Anwendung im Flugzeug- und Bootsbau

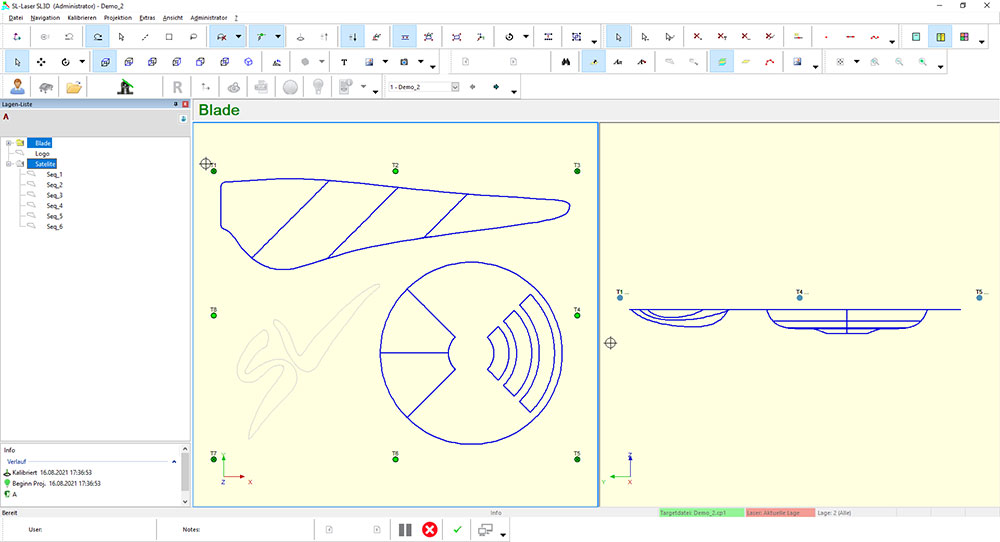

Die SL3D Software im Flugzeugbau

Mit der SL3D Software entfällt die Übertragung der räumlichen Koordinaten auf Papierdokumente und Schablonen. Die fehleranfälligen Übertragungen auf andere Größenverhältnisse werden durch den Import der 3D-CAD Daten überflüssig. Die 1:1 Projektion ermöglicht eine reibungslose Qualitätssicherung und Dokumentation, die alle Aufwände entscheidend reduziert und zur Kostensenkung beiträgt.

So kann die Fläche eines Halters auf den Rumpf projiziert und der Halter anschließend montiert werden. Zur Qualitätskontrolle projiziert man eine markante Kontur auf die sichtbare Oberfläche des montierten Halters und überprüft damit die Position.

Das Vermessen von Bauteilen im Bootsbau mit dem ProCollector L

Die Vermessung gekrümmter Räume mit traditionellen Messverfahren ist anspruchsvoll und fehlerbehaftet. Diese Fehler zeigen sich häufig erst bei der Endmontage – dann aber kostspielig. Der ProCollector L ist ideal für die Erhebung von Messdaten im Bootsbau. Alles, was vom Aufstellungsort aus sichtbar ist, lässt sich in 3D-Koordinaten erfassen. Der ProCollector L wird dann problemlos versetzt und vervollständigt die Messung aus einer geänderten Perspektive.

Die Messdaten werden anschließend in einem gebräuchlichen CAD-Format abgespeichert. Danach stehen sie sofort für die weitere Bearbeitung mit einem PC-basierten CAD-Paket bereit.

Spezielle Software für die Lagenbearbeitung

Bei der Verarbeitung von Composite-Materialien geht es immer auch um die Ausrichtung der Lagen. Die SL3D Software für den ProDirector 7 findet hierbei eine ideale Ergänzung durch die SL Assembly Software. Mit der Scan-Funktion erfolgt eine intelligente Erkennung gleicher Geometrien. Diese werden in einer Bibliothek abgelegt, wo sie in projizierbare Symbole umgearbeitet werden.

Wenn man sich bestimmte Komponenten von den Bauteilen anzeigen lassen will, kann die Assembly Software die Konturen einzeln anwählen und exportieren. Dann kann die schrittweise Projektion und Montage erfolgen.