Projektionssysteme in der Betonindustrie und im Baugewerbe

Der Einsatz der Projektionssysteme von SL Laser im Baugewerbe und für Betonfertigteile ist seit Jahrzehnten etabliert. Weltweit stellen sie präzise und maßstabsgetreu Umrisse, Muster und Formen auf Oberflächen dar. Mit den CAD-Daten als Grundlage erzeugen sie virtuelle, sichtbare Schablonen. Der ProDirector 7 vereinfacht und verbessert Prozesse, indem er selbst komplexe 3D-Informationen visualisiert. Aber SL Laser bietet noch mehr. Gerade im Baugewerbe kann mit dem Aufmaßsystem ProCollector L mühelos ein fehlerfreies Aufmaß für viele Produktions- und Montagevorgänge hergestellt und als Projektionsvorlage genutzt werden.

Vorteile für das Baugewerbe und die Betonfertigteile-Produktion

Der ProDirector 7 kalibriert sich auch im Verbundsystem selbstständig für präzise Projektionen auf dem Tisch.

Die Projektoren ermöglichen parallele Arbeitsschritte und erledigen gleichzeitig die Endkontrolle / Qualitätssicherung.

Der ProCollector L misst und projiziert CAD-Zeichnungen für einfache Kalibrierung selbst auf gekrümmten Oberflächen.

Eine anpassbare Software für die Integration in Steuerkonsolen und Leitsysteme für die Praxis verschiedener Umgebungen.

Typische Einsatzbereiche unserer Lasersysteme in diesen Bereichen

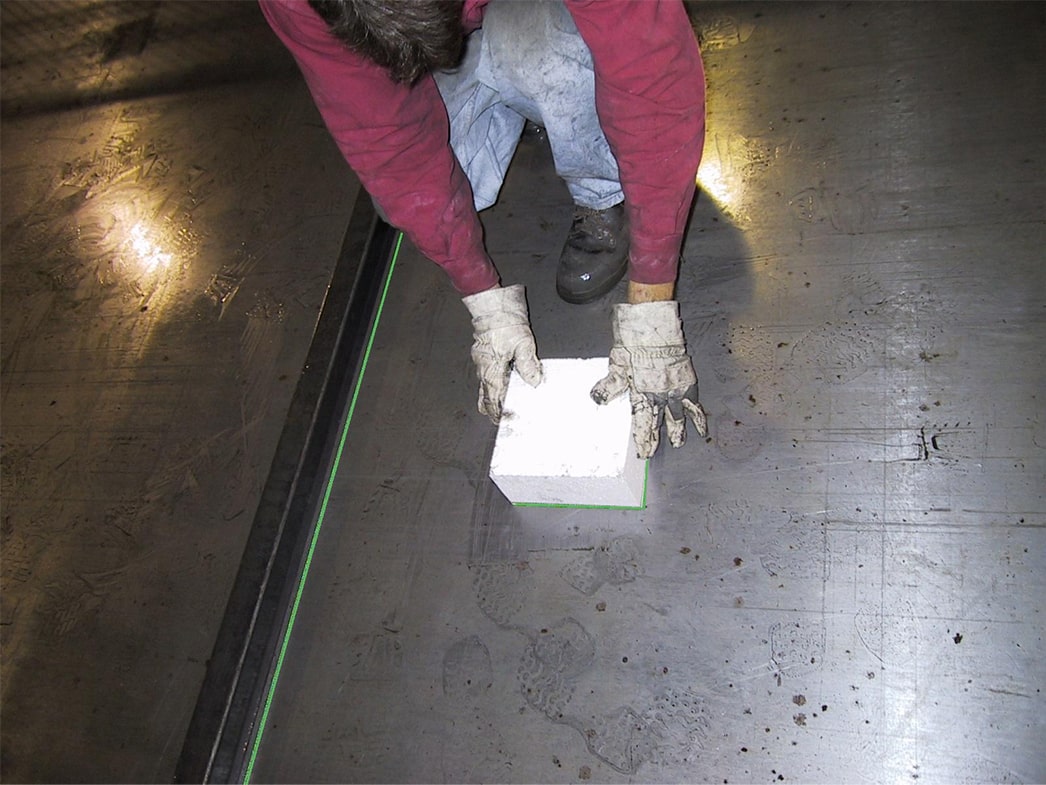

Der ProDirector 7 und der ProCollector L werden für verschiedene Prozesse im Baugewerbe und bei der Herstellung von Betonfertigteilen eingesetzt. Der ProDirector 7 kalibriert sich automatisch und projiziert Linien und Punkte im Verhältnis 1:1 auf den Tisch. Das ermöglicht die Positionierung von Rahmen, Bewehrungen und Schalungen. An langen Tisch-Applikationen arbeitet ein abgestimmtes Verbundsystem mehrerer Projektoren mit exakter Berechnung der Höhe und der Winkel. Der ProCollector L erfasst mit nur zwei Messpunkten pro senkrechter Fläche Daten und überträgt sie in das DXF-Format für CAD-Programme.

Weitere Informationen zur Anwendung in der Betonindustrie und im Baugewerbe

Der ProDirector 7 in der Betonindustrie

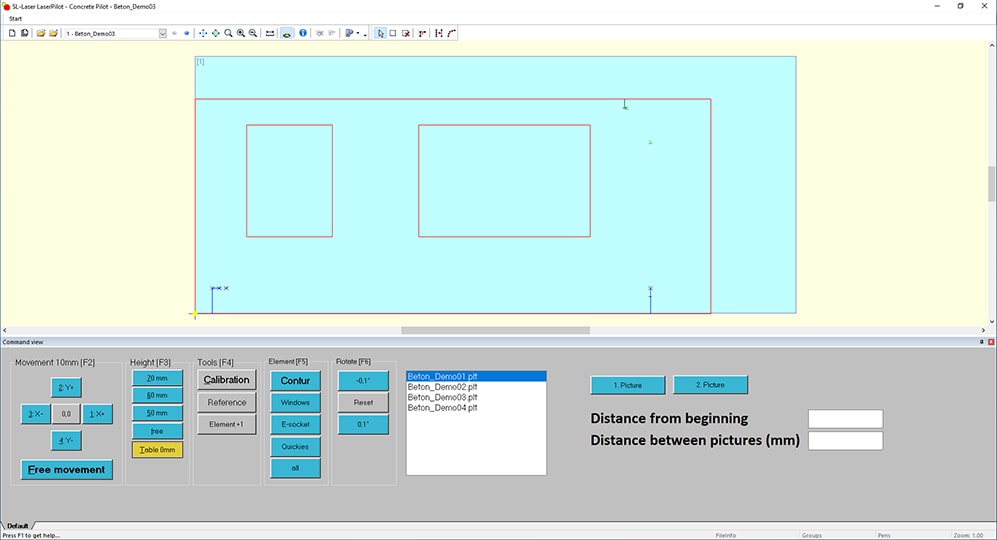

Mit einem Trolley auf Schienen kalibriert sich der ProDirector 7 automatisch auf den jeweiligen Positionen und projiziert alle notwendigen Markierungen für das jeweils bearbeitete Teilstück. Die dazu benötigten Daten aus dem CAD-System werden per Fernbedienung oder direkt auf dem Touchscreen des Industrie PCs von SL Laser angewählt. Die jeweiligen Aufgaben und Positionen der Rahmen, Dosen und Schalungen werden präzise projiziert.

Unsere Entwickler passen die Software gern auf die spezifischen Bedürfnisse an. So ist auch die Integration in die Steuerkonsole bzw. das Leitsystem der Bänder möglich.

Laserprojektion für Betonfertigteile

Bei der Arbeit mit Paletten kalibriert sich der ProDirector 7 für jede eintreffende Palette neu und projiziert die nötigen Arbeitsschritte. In der Umlaufanlage ermöglichen mehrere Projektoren an den jeweiligen Stationen eine gleichzeitige Bearbeitung auch unterschiedlicher Arbeitsschritte. So werden bei einem Durchgang Rahmen, Schalungen, Bewehrungen und die Endkontrolle parallel durchgeführt.

Die Endkontrolle und die Qualitätssicherung können damit zu einem Arbeitsvorgang zusammengefasst werden. Die erfassten Daten werden im System gespeichert und können im Berichtswesen verwendet werden.

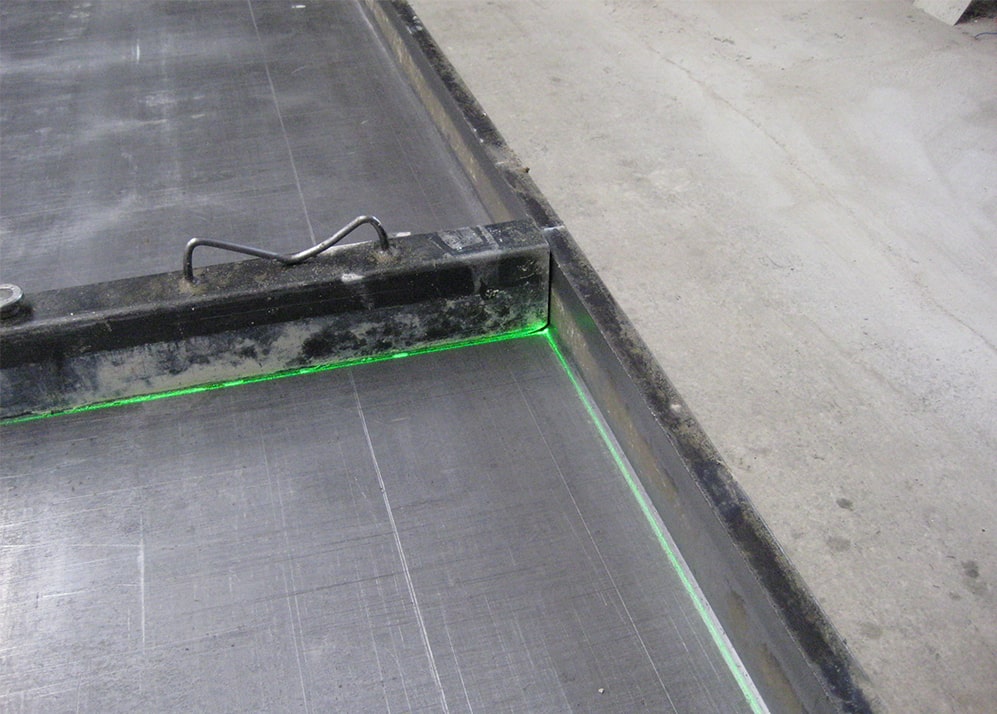

Die Arbeit mit dem Aufmaßsystem ProCollector L

Das Aufmaßsystem ProCollector L vermisst Flächen, Treppen und gekrümmte Oberflächen. Mit der einfachen Vorgehensweise entfallen die typischen Erfassungs- und Übertragungsfehler beim Anpeilen von Ecken und Kanten. Er projiziert eine von ihm berechnete oder bereits vorliegende CAD-Zeichnung auf das Werkstück oder jeweilige Bauteil und bildet damit den Grundriss ab.

Danach kann die genaue Kalibrierung auf der zu bearbeitenden Fläche durchgeführt werden. Das bedeutet eine erhebliche Arbeitserleichterung. Nach der Weiterbearbeitung der Daten können diese ohne Zeitverlust an die Fertigung übertragen werden.