Laser in manufacturing

- Laser technology for manufacturing means significant time savings

- Automated projection of work steps increases precision

- Reduce the error rate, employee satisfaction increases

- Facilitate quality management with precise specifications

- Achieve a clear competitive advantage in your market segment

Around the world, thousands of our systems support companies in craft and industrial manufacturing. Laser projectors like the ProDirector 7 and the positioning lasers enjoy the best reputation. They optimize work processes and results. After installation, employees show their enthusiasm in a very short time: the handling is so self-explanatory that the changeover is quick and trouble-free.

Software that specializes in the various industries and their task areas helps with this. Rejects are reduced and the work is clearly easier to handle. The positioning lasers and laser projectors are as resilient as they are robust in any environment.

Suitable products for manufacturing

Laser light projector ProDirector 7

The ProDirector 7 projects under the ceiling, the next work steps or entire construction plans from the 2D CAD or 3D CAD system onto the workpieces. Can be used for distances from the laser to the application of up to 6 m.

Laser Projector

ProDirector 7

System specifications

Position Accuracy

±0.014“ (0.35 mm) at a distance of 15‘ over 17‘ x 17‘ (4.5 m x 4.5 m) area (equals to a 60° projection)

Field of View

Horizontal: max. 80°, Vertical: max. 70°

Laser

Green: 520-525 nm, FC-lasermodule

Laser Class 5 mW

International: Class 2M per IEC/EN 60825-1:2015-07, CE certification

USA: Class IIIa per 21CFR 1040 (CDRH)

Power Requirement

80-240 VAC 50/60 Hz

Dimensions

Length: 355 mm/18.90 “, Width: 120 mm/6.69 “, Height: 190 mm/11.42 “, Weight: 5,8 kg

Our positioning lasers for manufacturing

System specifications of the

positioning lasers

Mechanics

Housing anodised aluminium, dimensions (mm) Ø 30 x 88.5mm, weight 300g incl. cable

Optics

Line or cross, homogeneous line

Optical properties green

Diode laser, diode power: 10 mW / 50 mW, wavelength 520nm (green), lifetime: > 20,000 h

Optical properties red

Diode laser, diode power: 10 mW, wavelength 635nm (red), service life: > 20,000 h

Laser class

Class 2M at 10 mW (Class 3R at 50 mW) EN 60825-1:2015-07, IEC60825-1, EN76-2, 21CFR 1040, CE

Testing and safety

Temperature range 0°C… +50°C, housing IP 65, shock load 4 g

Electrical data

Voltage 16-33 VDC (+)bn (-)bl (PE) gb/gn, power consumption 1 W, supply cable 5 m

Product and performance data v

for the positioning lasers at SL Laser

These data are used as example data.

On request, our positioning lasers can be adapted to your needs.

| Laser colour | Power Diode | Output power | Focusable | Optics | Laser class |

|---|---|---|---|---|---|

| green | 10 mW | < 1 mW | yes | Line | 2M |

| green | 10 mW | < 1 mW | yes | Cross | 2M |

| green | 50 mW | < 5 mW | yes | Line | 3R |

| red | 10 mW | < 1 mW | yes | Line | 2M |

| red | 10 mW | < 1 mW | yes | Cross | 2M |

| Line generator for line length 10°, 15°, 30°, 45°, 60°, 90° | |||||

Do you have questions?

Get in touch – we’re here for you. Our customer service team is happy to provide personal advice and individual support.

Laser in manufacturing

Various manufacturing processes from practice

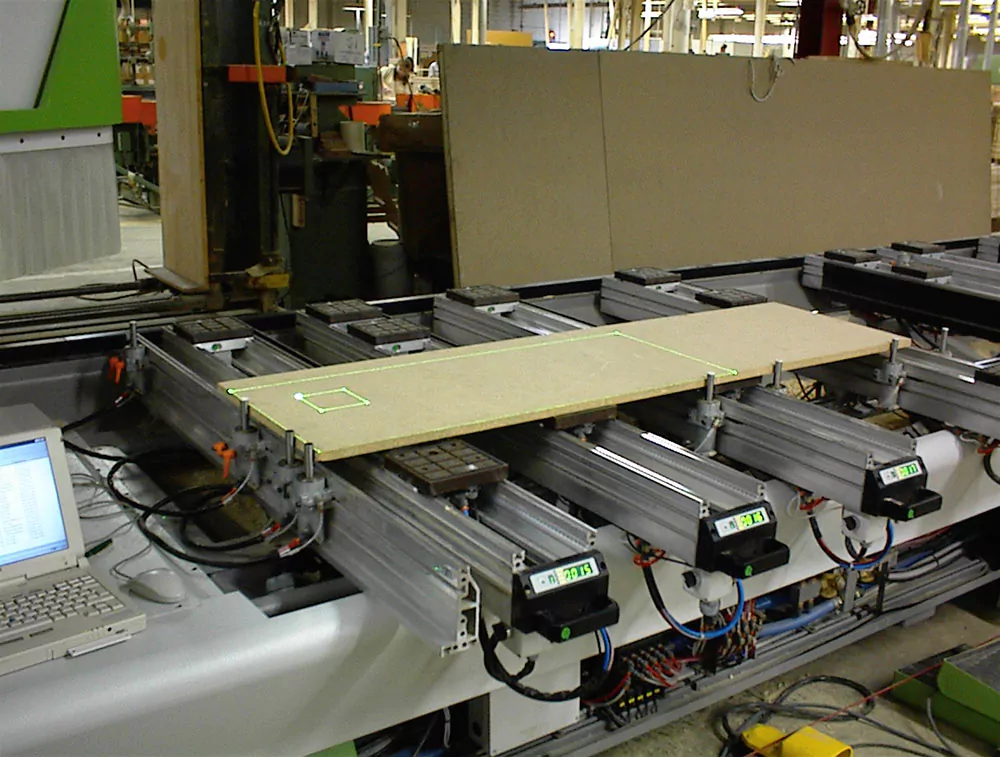

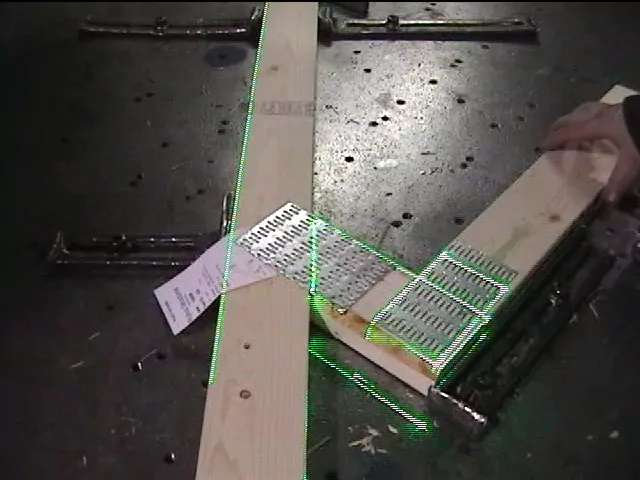

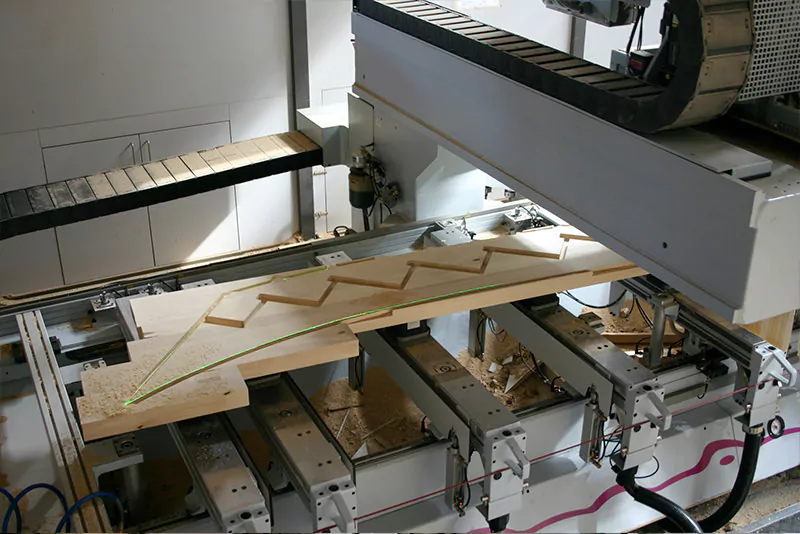

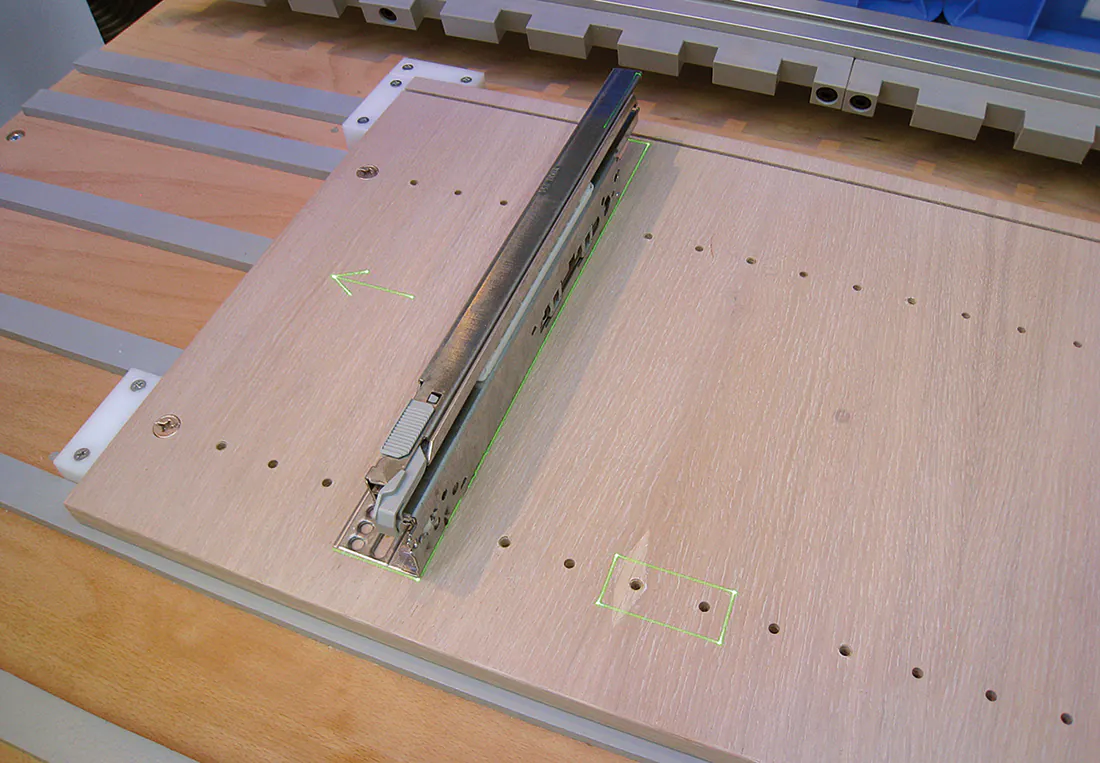

Since the late 80’s, lasers have proven themselves in the manufacturing technology of wooden parts. Setting up CNC routers becomes child’s play with laser beams. Just like the suction cups, the workpieces can be positioned so precisely and quickly that no more damage occurs. The same applies to the often laborious positioning of fittings in furniture production. Quality control is accelerated and facilitated. The margin of error and scrap in this manufacturing process are significantly reduced.

Whether on the construction site or during production on the shop floor – today it is laser radiation that speeds up work and improves results in manufacturing technology. When frames, reinforcements or formwork are positioned and checked, it is the data from the CAD program that our systems translate and project into clearly recognizable points or lines. In various manufacturing processes, the laser works in the production in the compound system on rails or, for example, permanently mounted in the pallet circulation system. On the building site, two measuring points on the surface are sufficient for the ProCollector L so that the floor plan can go into production.

In more and more industries, different layers and materials are entering the manufacturing technology as a composite. It is the laser projector that marks the contours and thus provides the precise templates for the work. In automotive engineering, fiber mats are positioned and laid by laser. Here, but also in the aerospace industry, precise documentation is essential – a task that is supported in parallel by the laser projector via software. Today, manufacturing quality management processes are almost inconceivable without the use of our systems. There is hardly a company left without laser projection in the basics of manufacturing technology.

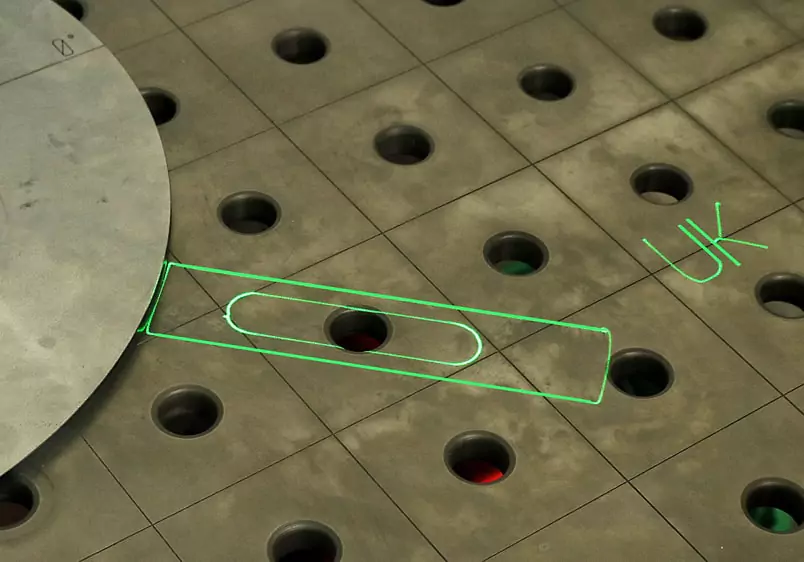

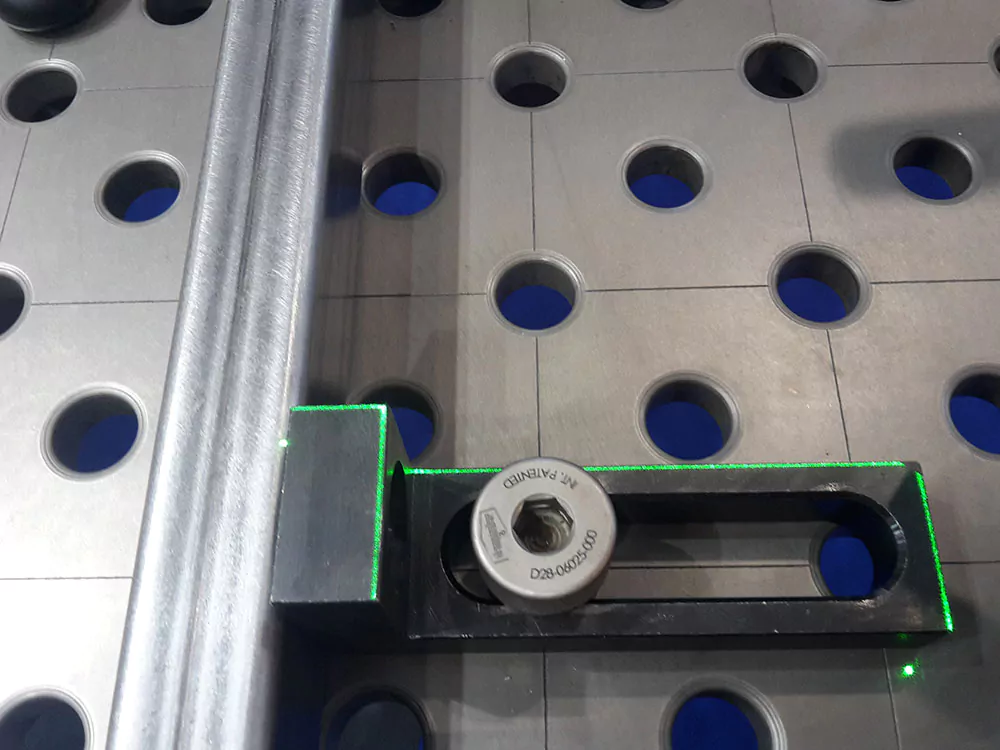

Whether for manual drilling or machine-assisted welding, manufacturing technology in metalworking only becomes truly competitive with the technology of the laser projector and positioning laser. With the stored positions of the work surfaces, the software and the laser play in the projection for the machining of the workpieces layer by layer. The error-prone preparation of templates as the basis of the work is no longer necessary. On the welding table, the data from the CAD program is converted into laser projections accurate to the millimeter. Workpieces and clamping devices fit the first time. Setup repetitions are no longer a special matter.

Many manufacturing processes in textile processing have been revolutionized by our systems and their application possibilities. This is especially true for the individual production of large workpieces. Tarpaulins, balloons, covers – all of these are facilitated by laser processes. Because the precise specifications make expensive offcuts an absolute exception. In textile processing, stencil making in particular represents an unpopular expense for employees, which is now a thing of the past with the use of laser radiation for production technology. The costs decrease, the yield increases.

Our customer service

From the very beginning of the company with the first devices for laser projection, we have placed the greatest emphasis on highly reliable after-sales service and support. From explaining the basics of the technology, such as the beam sources, to providing hands-on introduction to highly customized applications in specialized operations, it is our after-sales service that has established and promoted SL Laser’s reputation ever since. Our professionals have acquired exactly the expertise it takes through a multitude of on-site installations and introductory training.

The employees lose their fear of contact with the new technology and the beam sources. They quickly and playfully familiarize themselves with the practical application of the systems. Even with the first trial installation, the work is productive. Back at home, the customer service helps by phone or connected to the computer. This is the service that all our customers appreciate time and again.

Just give us a call. We will support you before and after your order.