Ceiling laser for industry and craft

- Laser projectors that have been inspiring the world for 35 years

- Thousands of devices successfully in use in many industries

- Production processes are simplified and accelerated

- Robust and dust-tight in use – reliable and precise

- Self-explanatory in handling – useful for your company

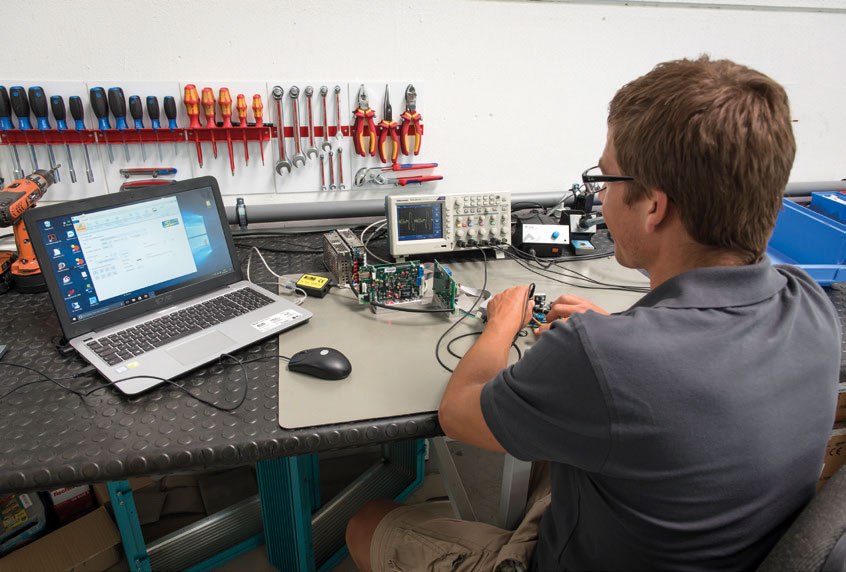

SL Laser’s laser projectors have set the standard since the early days of laser projection. They can be found in almost every country and have made a name for themselves across many industries. Business owners appreciate the precise work that reduces error margins and increases profits. Colleagues appreciate the reduced workload and increased profits. There is less scrap and the creation of laborious templates can usually be eliminated. With on-site training, the changeover is child’s play.

Functionality as a ceiling laser for craft and industry

System specifications for the ProDirector 7

- Position Accuracy

±0.014“ (0.35 mm) at a distance of 15‘ over 17‘ x 17‘ (4.5 m x 4.5 m) area (equals to a 60° projection) - Field of View

Horizontal: max. 80°, Vertical: max. 70° - Laser

Green: 520-525 nm, FC-lasermodule - Laser Class 5 mW

International: Class 2M per IEC/EN 60825-1:2015-07, CE certification

USA: Class IIIa per 21CFR 1040 (CDRH) - Power Requirement

80-240 VAC 50/60 Hz - Dimensions

Length: 355 mm/18.90 “, Width: 120 mm/6.69 “, Height: 190 mm/11.42 “, Weight: 5,8 kg

The 3D laser projection by ceiling laser, cross line laser or line laser

The cross line lasers, positioning lasers and line lasers are so successful that they have long since arrived at the DIY enthusiasts. But in industry and trade, it is now ceiling lasers such as the ProDirector 7 from SL Laser that have long set the standards for successful work. Unlike cross line lasers, for example, ceiling lasers such as the ProDirector 7 take over all important data directly from the CAD program. Whether the position of workpieces, suction cups, drill holes or weld seams – the work is done quickly and precisely without the time-consuming templates or readjustment of the lasers.

The next shift or level is projected at the push of a button. As a rule, working time is reduced by 25%. In return, convincing precision is achieved, the quality of the products increases and quality control is made much easier. The colleague simply repeats the projection steps and checks the performance. All without tedious measuring and transferring of plans.

Hardware performance description

- Aluminum housing (IP 54) optimized for heat dissipation

- Electronics with SMD technology

- Integrated PC with 800 MHz, 4 GB memory

- Data transmission: RS232, RS 485, or fiber optic cable

- Control diodes for mains voltage and information signal

- High speed scanner with push-pull output stages

- Ambient temperature 5-45 degrees, power consumption approx. 70 VA

- Optimized reception sensor of the reflection radiation

- Mains filter in the power supply line

- Switching power supply with an input voltage of 100- 240 VAC

- CE conformity marking, manual

Do you have

any questions?

Contact us.

The advantages of using ProDirector 7

A ceiling laser offers many advantages. A few of them are obvious. Mounted under the ceiling, the laser can neither interfere with the processes nor suffer mechanical damage. Not to mention that the laser projectors are built so robustly that they can withstand even hard loads together with the industrial PC. But under the ceiling of a normal factory hall, the range of projection of the laser beams increases at the same time. With the performance of our ceiling lasers, the required degree of precision is achieved with ease. The respective angles for calibration or adjustment are automatically calculated by the software. In doing so, the ProDirector 7 achieves a projection field for the laser of up to 80° degrees horizontally and 70° vertically for each direction in the room.

Users in the aerospace and construction industries require appropriate extensions for their sometimes very large factory halls. For example, the ProDirector 7 can be mounted on a rail system, with the respective holding points at the various positions already stored in the software. In other cases, the laser projector is used as a compound system. Whether for covering large areas or for imaging and displaying 3D data, different laser projectors are simply connected together. Our customer service specialists provide all the necessary information and of course support the installation on site.

ProDirector 7 – indispensable in many industries

From wood to stone to metal

On our website we have described the different industries and applications exactly for you. The CNC routers in woodworking made the beginning in the early nineties. Since then, the technology has not only improved significantly, but has expanded to almost all industries after wood. The contours for the various layers in composite applications in the automotive industry or in wind energy use can be machined with the same automated precision as the various stations of a pallet circulation system in the concrete industry. The control of different planes during the manual machining of metal parts facilitates the work, as does the 1:1 projection for steel trusses.

Work facilitation and higher precision at all levels

Thanks to laser projectors, the demands for the absolutely necessary highest precision in aerospace have been met just as easily as quality control in quality management. If, in addition, the laborious documentation of work processes is also supported by the software, no one seriously wants to do without the ceiling lasers anymore. Line lasers and cross line lasers are still welcome at work. However, the use of CAD program, specialized software and the ProDirector 7 as a set in the composite system can hardly be compared to this. This is more of a fully integrated system solution.

The individual adaptation to specific needs

With all the expansion of technology and optimization of software, we at SL Laser place the greatest value on the simplicity and comprehensibility of the design itself. This brings various advantages. Not only that the colleagues on site or later in the support by the customer service do not need studies and special training to keep track of the equipment and accessories. We are also able to develop highly individual solutions for very specific requirements quickly and at a reasonable price. For example, the joint control of laser projector and CNC system from the same control panel has been realized many years ago.

Successful from day one

The ProDirector is just as well known in industry as it is in the trades. Whether it is an entire compound system or whether individually commissioned production is accelerated in the trade – in every case, the ceiling laser proves to be an asset. The secret lies in the professional installation and the easily comprehensible training by our experts. Often, the understandable fears of contact can be dispelled in the first few hours of handling the ceiling laser. After a few days, the colleagues are fit. Often, we can simply put the trial installation into operation, mounted on site.

More profit with ProDirector 7

Do you already work with the line laser, positioning laser or cross line laser in your company? Perhaps adding a ceiling laser to your laser technology would be the perfect way to optimize your workflows and increase your profits. Even in the trades, virtually all of our customers report that investing in a ceiling laser like the PoDirector 7 has paid for itself after a relatively short period of time. With accelerated job completion and less scrap, you can also outperform your competitors’ bids. Ensure the success of your work. Get in touch with us.

Customer service and support

A technology can be long-established and highly proven. But as soon as it is newly deployed in a plant or company, the service and after-sales support must work perfectly. Our training courses on trial installations on site are strictly user-related – and precisely to the users from your company. What use are theoretical basics when a system is to be operated?

The overview must be there. From the first installation to the application in practice to after-sales service via telephone or remote maintenance – at SL Laser we have always focused on fast and cost-effective solutions in your interest. Our worldwide success with thousands of systems in operation proves us right and spurs us on.

Contact us at any time. We will gladly answer all questions without obligation!