Laser projection in the aircraft and boat building industry

SL Laser has established itself as the number one supplier for the work with laser projection among the leading aerospace manufacturers in Europe.. On the one hand, the precision, reliability and ease of use of the laser projectors are highly valued. On the other hand, the specific adaptations to the software and applications that we carry out at the request of the customer score highly. The same applies to boatbuilding. In addition, it is the measurement systems that simplify the collection of the necessary measurement data, even in narrow and curved spaces.

Advantages for the aviation industry and boatbuilding

Precise projection reduces assembly errors in aircraft construction and considerably simplifies quality assurance.

In boat building, the ProDirector’s projection enables error-free positioning and fastening of material layers.

In aircraft construction, error-prone transfers with templates are no longer necessary and allow a direct 1:1 projection.

The ProCollector L revolutionizes measuring in boat building. It captures precise 3D coordinates even in difficult areas.

Suitable products for aircraft and boat building

Typical areas of application for our lasers in aircraft construction and boat building

In aircraft construction, SL Laser projectors are used for composite materials as well as in assembly. Here, a large number of brackets, clamps, screws and switches have to be drilled and assembled with the utmost precision. You will love the use of projection in quality assurance, which can be carried out seamlessly in the next work step. In boatbuilding, error-free positioning and fastening is important. This is made possible by the display and precise projection of the individual layers, their geometry and dimensions. The compact design of the ProDirector 7 allows contours and assembly parts to be displayed in confined spaces.

Further information on the application in aircraft and boat construction

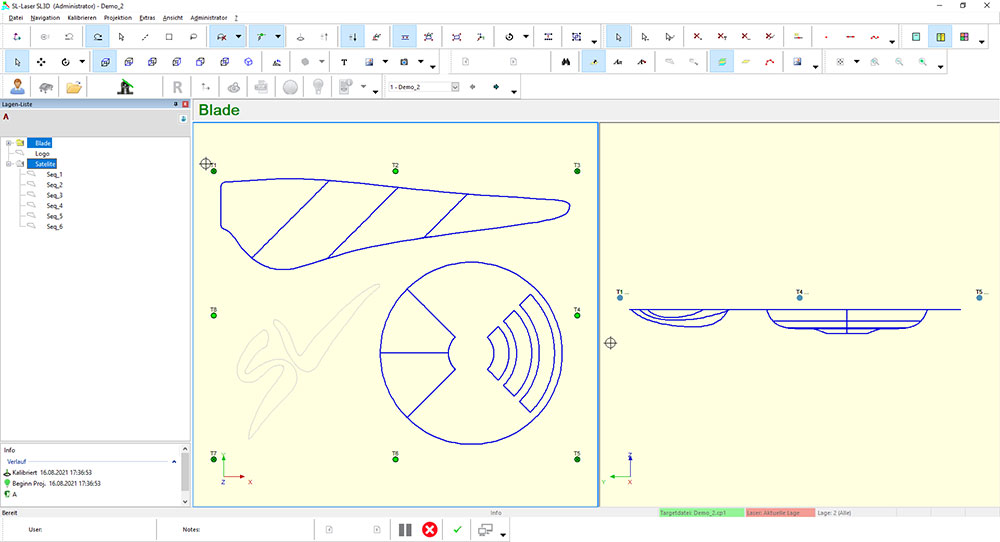

The SL3D software in aircraft construction

SL3D software eliminates the need to transfer spatial coordinates to paper documents and templates. The error-prone transfers to other dimensions are no longer necessary thanks to the import of 3D CAD data. The 1:1 projection enables smooth quality assurance and documentation, which significantly reduces all work and contributes to lower costs.

The surface of a holder can be projected onto the fuselage and the holder can then be assembled. For quality control purposes, a distinctive contour is projected onto the visible surface of the mounted holder and used to check the position.

Measuring components in boatbuilding with the ProCollector L

Measuring curved spaces using traditional measuring methods is challenging and prone to errors. These errors often only become apparent during final assembly – but are then costly. The ProCollector L is ideal for collecting measurement data in boatbuilding. Everything that is visible from the installation site can be recorded in 3D coordinates. The ProCollector L is then easily moved and completes the measurement from a different perspective.

The measurement data is then saved in a standard CAD format. They are then immediately available for further processing with a PC-based CAD package.

Special software for layer processing

The processing of composite materials always involves the alignment of the layers. The SL3D software for the ProDirector 7 is ideally complemented by the SL Assembly software. The scan function intelligently recognizes identical geometries. These are stored in a library where they are converted into projectable symbols.

If you want to display specific components of the parts, the assembly software can select and export the contours individually. Then the step-by-step projection and assembly can take place.