TrussPilot

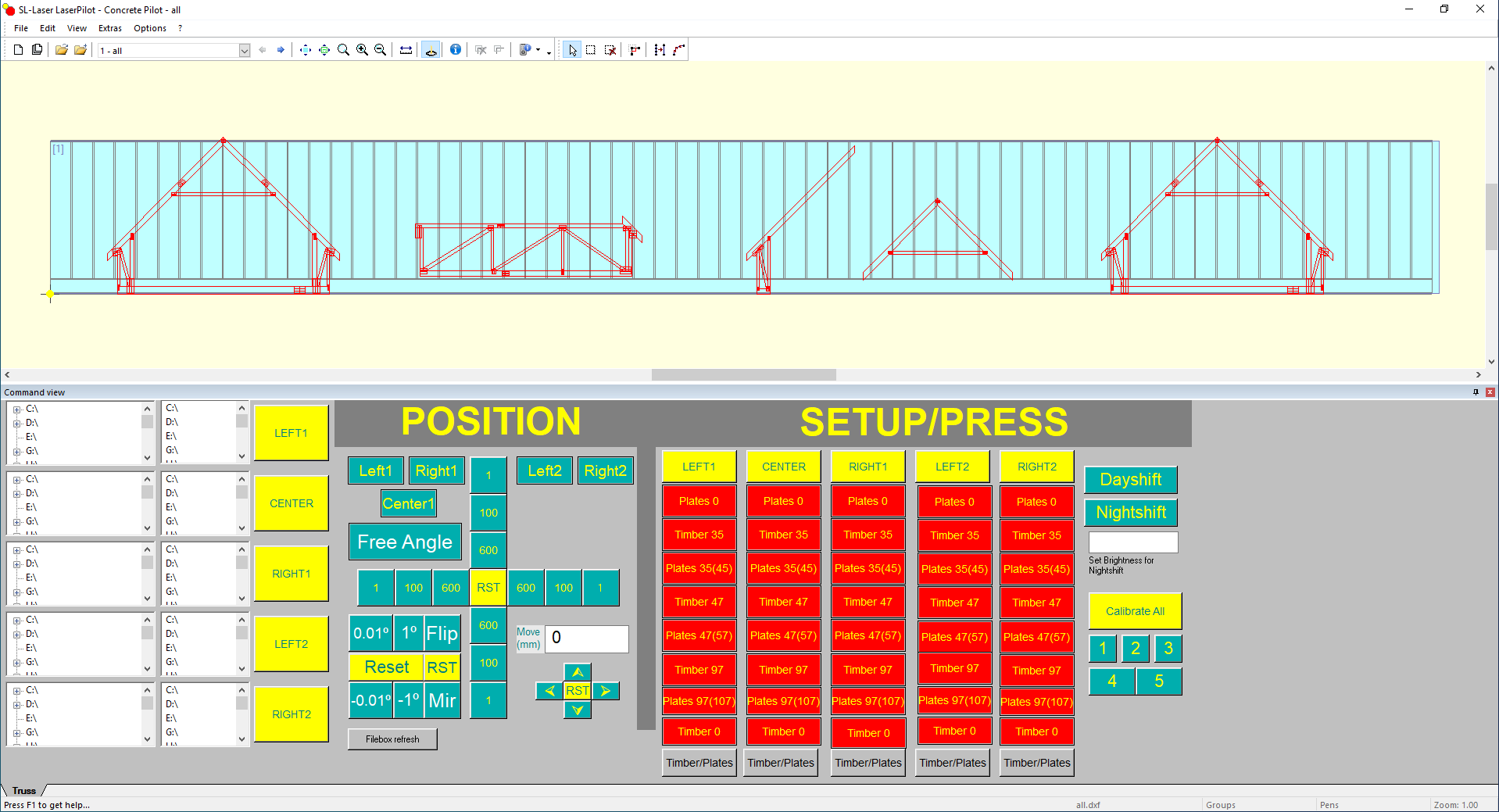

SL Laser TrussPilot software puts you in the captain’s chair. From job batching to truss positioning to management reporting, you’re in command! With an intuitive operator interface, projecting truss templates is as easy as opening e-mail.

The software for the structural building component industry

Your builders will be spending less time jigging setups and more time rolling trusses out the shipping door. Immediately. Period.

Working with TrussPilot

The TrussPilot menu and control areas are completely configurable to allow the user to create an interface that can be easily learned and operated by plant-floor personel. The on-screen control buttons can be custom designed and triggered at the table with remote controls.

Every SL Laser Truss Projection System is custom-tailored to your building process by a SL Laser factory-trained technician. This system can be easily modified by anyone with basic software skills using a well documented command set of control options.

The system is password-protected to prevent tampering by unauthorized personel. As many as eight different build teams can work on a single truss table – each with its own remote control. Each projector is capable of projecting multiple images in each projection zone to overlap jobs and get the most out of your table space.

PC Requirements

Windows Operating System (Windows 7 or newer) with a pointing device and available USB port. TrussPilot can control multiple laser projectors on a single system.

Definition:

Component control

If you use a puck system for jigging, you can project a truss outline to quickly set the pucks to the laser line.

If you use blocking, project the chords to the table level and nail the blocking to the laser line. With the push of a button, go to the next step in the process. Set your chords, set your webs, project the plate locations, and you’re off to the next setup. Fast. Simple.

Positioning

You can move, flip, mirror, and rotate trusses to get the optimum position on your table. Select the top chord of a scissor truss and snap that chord to your baseline to minimize jigging.

Batching

Schedule your upcoming shifts by syncronizing the projection sequence with your material flow. Move trusses out of a .tps file to build them at a different station. Split a job file between two build teams. All the builder has to do is push the “Next Truss” button on his remote control to keep the trusses flowing!

Management Reporting

Which shift is spending the most time on setups? Which trusses are taking the longest to produce? Which build team is making you the most money? Find out with TrussPilot management reports.

Do you have

any questions?

Contact us.