SL3D

From ply batching to ply positioning to management reporting, you’re in command! With an intuitive operator interface, projecting ply templates is as easy as opening e-mail. Your builders will be spending less time manufacturing complex composite parts. Immediately. Period.

The SL3D software for composite applications

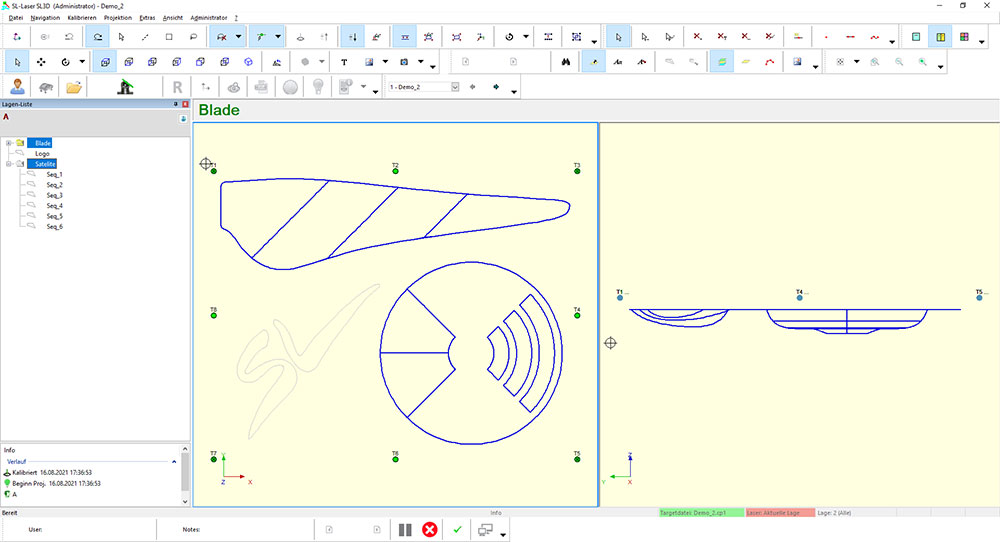

The SL3D software is used to project three-dimensional drawing data. SL3D provides a number of functions for editing existing drawing files from CAD programs and adapting them for laser projection.

Working with the SL3D software

It is possible to use several projectors simultaneously and to use several objects like e.g.to project forms at the same time.

SL3D supports the distribution of the projected drawing elements in an intelligent or automatic way.

For the control and documentation of the production process of e.g. carbon fiber parts have many features and options. SL3D displays image content in up to 4 windows simultaneously. For an image, a supporting bitmap, JPEG or PDF with descriptions e.g. of the work process are displayed.

PC requirements

Windows Operating System (Windows 7 or newer, 64 bit, 4 GB RAM, 1 GB graphics memory) with a pointing device and available USB port. SL3D can control multiple laser projectors or a single system.

Short description:

Electronic Ply book

Time stamp, ply name, Operator

Modify Ply data

Hide or Delete lines, reduce points

Data input

From CAD Systems such as CATIA, ProE

Import Formats

IGES, STEP, DXF, APT, PLY, SL, GSI, XML

Automated tools

Automatic selection of the ideal projector

Security and Process Security

Password protected, workflow protected, online guides, enforced brakes

Graphical 3D view

Multi mould calibration

working on independent moulds

Extra online-guides for production as text or graphical information that is displayed on the screen with the corresponding ply. E.g. a drawing or photo how to do perform this step. The information is shown by the programmers button click or automatically when the ply is selected.

Enforced “brakes” that guarantee a minimum timing for certain steps. E.g. after applying the vacuum bagging a countdown starts for five minutes to ensure the required time for compacting.

Do you have

any questions?

Contact us.