SL Assembly

Die SL Assembly Software wurde speziell für Kunden entwickelt, die auf eine schnelle und einfache Art und Weise Projektionsdateien erstellen wollen.

Die Software zum Erstellen von Projektionsdateien

Vorteile, die SL Assembly bietet:

- Einfache Benutzung

- Daten werden schnell erzeugt

- Keine spezielle CAD Software für Datenerstellung nötig

- Keine Kenntnisse in CAD erforderlich

- Gutes Preis-Leistungs-Verhältnis

Die Software wird in 3 Module mit eigenen Lizenzen aufgeteilt.

Modul 1

Beim Kauf eines Projektors ist das Modul 1 im Lieferumfang enthalten.

- Projektionsdateien können ohne weiteren Eingriff in der Produktion benutzt werden.

- Es dient dem Vorbereiten und Optimieren der Projektionsdatei.

- Kalibrierdateien werden erstellt und Laserparameter werden eingestellt.

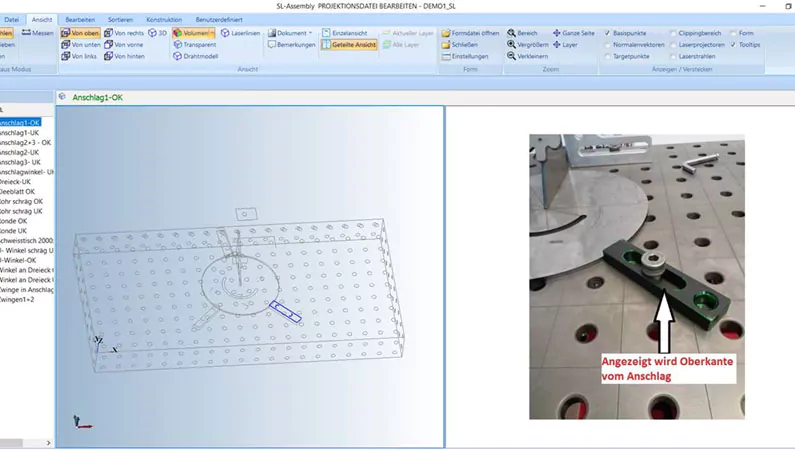

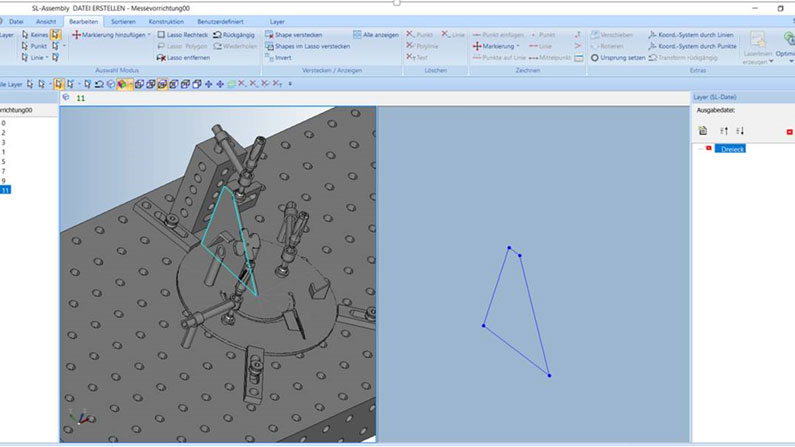

Modul 2

- Die doppelte Anzeige vereinfacht die Bearbeitung.

- Es dient der Erstellung von Projektionsdaten ausgehend von 3D Originaldateien.

- Eigene Projektionsabfolgen werden erstellt.

Für jede Abfolge können spezifische Linien der 3D Datei durch verschiedene Werkzeuge einfach und schnell in die Projektionsdatei übernommen werden.

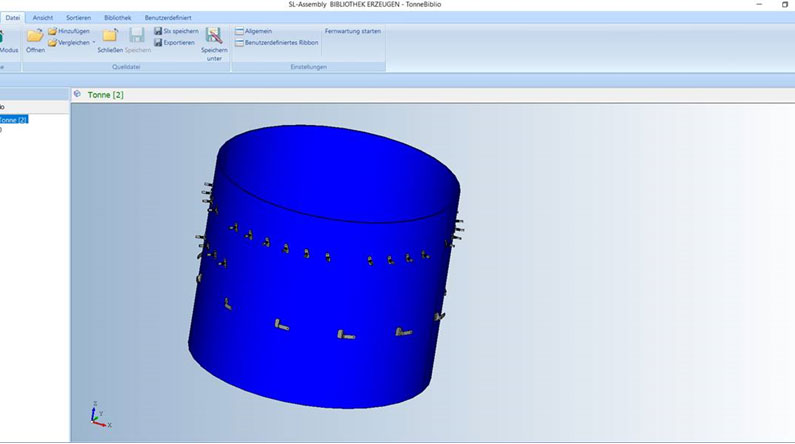

Modul 3

Bei einem Bauteil, das Elemente (z.B. Clips, Halterung,…) mehrfach enthält, kann eine Bibliothek erzeugt werden. Die Software scannt das komplette Bauteil nach Elementen ab und erstellt automatisch über die Bibliothek die Projektionsdatei.

PC Anforderungen

Windows Betriebssystem (ab Windows 7, 64bit, 4 GB RAM, 1 GB Grafikspeicher) mit Maus und einer freien seriellen oder USB Schnittstelle. Die SL3D Software kann mehrere oder einzelne Laserprojektoren ansteuern.

Sie haben Fragen?

Kontaktieren Sie uns – wir sind für Sie da. Unser Kundenservice steht Ihnen mit persönlicher Beratung und individuellem Support gerne zur Seite.

FAQ für SL Assembly

Nein! Ein Verständnis für Zeichnungen und eine Vorab-Vorbereitung welche Linienzüge ich auf meinem Werkzeug mit dem Laser anzeigen möchte ist die Grundlage, um die Software nutzen zu können.

Die Software ist einfach zu bedienen und viele Schritte erklären sich von selbst.

Im SL Format, dieses wird auch von der SL3D Software unterstützt. DXF und PLY sind auch möglich abzuspeichern.

Ja, wenn diese vorab in IGES oder STEP konvertiert wurden. PLY Daten werden auch geöffnet.

Ja! Es besteht die Möglichkeit ein Ansichtsfenster dafür zu nutzen. Dort können PDF, JPG, PNG, BMP oder einfach nur Text angezeigt werden. Es dient dem Anwender als zusätzliche Erklärung für die Zeichnung oder den Abschnitt.

Von Windows 7 bis Windows 11 einsetzbar.

Der Kunde erhält die gleiche Version, die er beim Kauf erhalten hat.

Standard PC. Ein i5 Prozessor reicht aus.

STEP, IGES, DXF, PLY, SL, SLX, APT, GSI, .txt, XML

- Modul 1 ist fast identisch mit der SL3D Software. Die Daten werden optimiert und für die Produktion zur Verfügung gestellt.

- Modul 2 dient dazu Daten für die Projektion zu erstellen. Dies können Linienzüge, Kurven, Punkte sein, die aus einer vorhandenen Zeichnung entnommen werden und dann für die Produktion vereinfacht werden.

- Modul 3 dient dazu wiederkehrende Bauteile in einer Bibliothek abzuspeichern als vereinfachte Darstellung. Das Programm scannt die Originalzeichnung und vereinfacht diese Bauteile.