Laser projectors from SL Laser in the metal industry

With its variants for medium and long distances, the ProDirector 7 supports the precision and efficiency of production in almost all work steps in metal processing. This is why our customers are spread across the entire industry. Large metal construction companies use entire series of laser projectors individually or as part of a network system in almost every production department. Many workshops and metalworking shops are making their work much more precise and faster, thereby securing competitive advantages. In the metalworking sector in particular, projector support plays an important role in quality assurance.

Advantages for the metal industry

Precise projection and therefore positioning of cutting, bending and forming lines on all metal parts with the ProDirector.

Millimeter-precise positioning with the welding data from the CAD programs. Simplified, accelerated quality control.

Set-up times are reduced by up to 70% when working with steel trusses. Seamless and fast adaptation to changes.

Compatible with CAD systems, the serial display of work steps and the parallel work of teams is supported.

Suitable products for the metal industry

Laser Projektor ProDirector 7

Software SL Assembly

Individual solutions

Suitable products for the metal industry

Laser light projector ProDirector 7

The ProDirector 7 projects under the ceiling, the next work steps or entire construction plans from the 2D CAD or 3D CAD system onto the workpieces. Can be used for distances from the laser to the application of up to 6 m.

Typical areas of application for our lasers in the metal industry

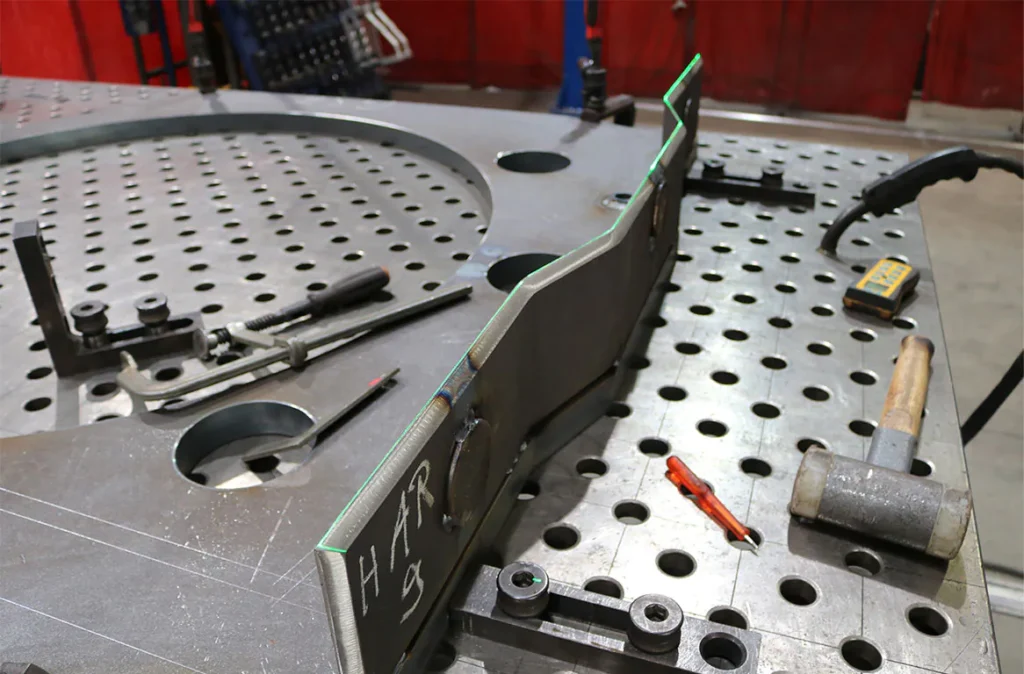

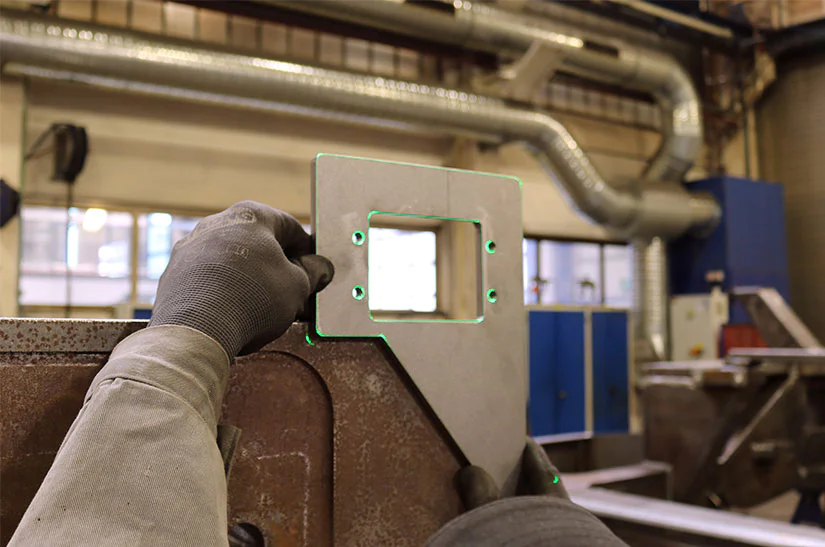

In the layout process of metal parts, the laser projectors from SL Laser enable the exact visual representation of designs on the raw material. They mark the cutting lines and contours for the cutting of metal parts and help with the precise marking of bending and forming lines. ProDirector 7 simplifies the correct alignment of metal parts before starting the precise positioning and guidance for welding work on the weld seams. It shows the exact positions and depths for drilling and milling work. Finally, it supports the correct positioning of components during assembly processes.

Further information on the application for metalworking

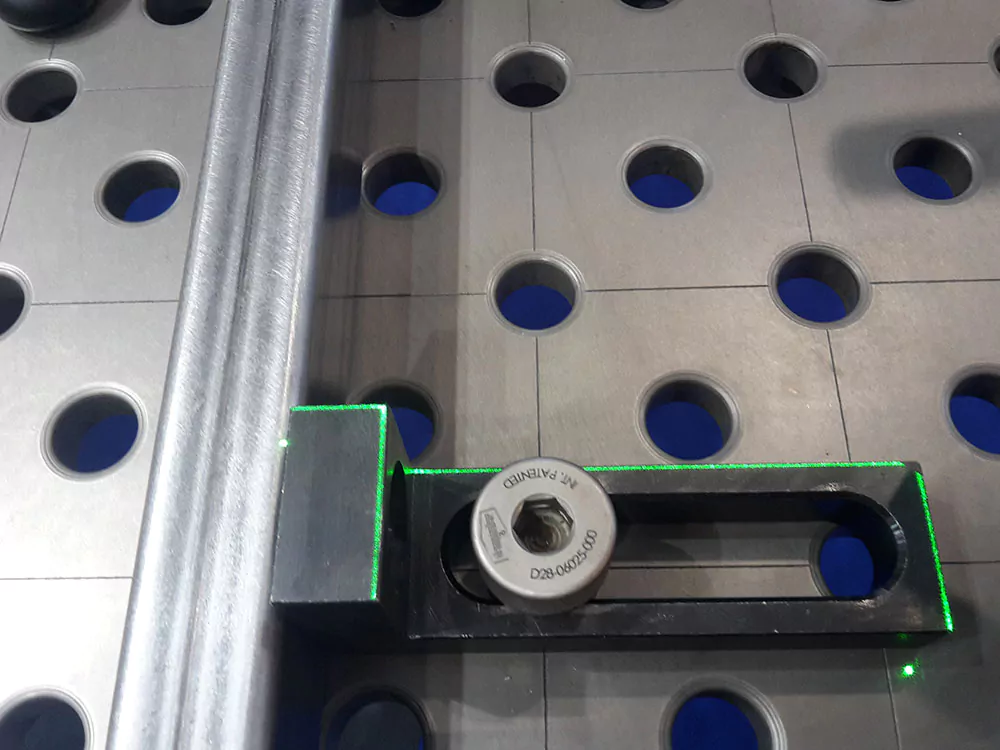

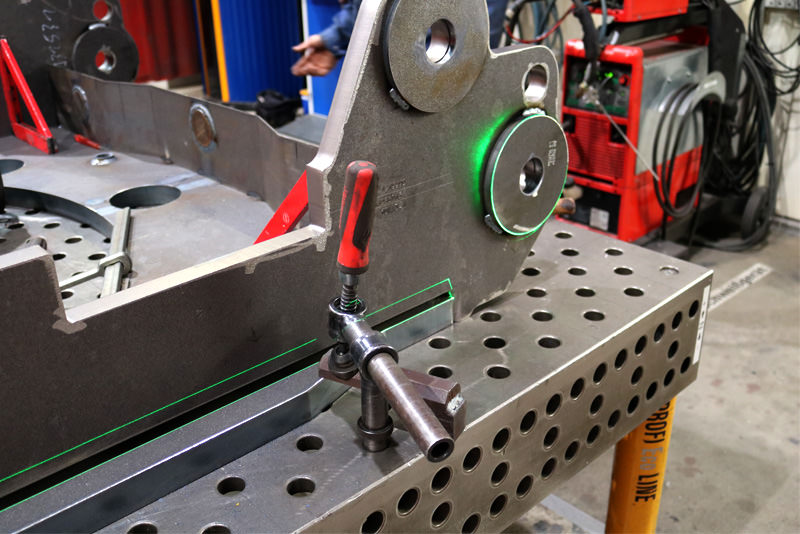

ProDirector 7 makes work on the welding table much easier. The data for the projection comes directly from the CAD program and is projected true to scale from any height. The 1:1 scale not only makes it easier to position the workpieces with millimeter precision, but also allows the clamping devices to be precisely aligned.

All set-up specifications are implemented precisely without the need for complex templates and no attachments are forgotten. The usual set-up repetitions become totally easy with the projection. Quality control is greatly facilitated and saved at the same time.

The set-up times for steel trusses are usually extremely time-consuming. This time can be reduced by up to 70% with the ProDirector 7. With the 1:1 scale projection, the contour of the truss is first displayed with millimeter precision. In the next step, the ProDirector remotely displays the stop position and the exact positions for the screw connections. This means that an application can be set up in the shortest possible time.

If the set-up status changes, the software used sends the changed data to the ProDirector, which immediately displays the new positions.

The LaserPilot software is part of the software program developed by SL Laser specifically for the various industries. It is compatible with the usual CAD systems and converts the required data effortlessly. This increases the productivity of the work. Drawings can be implemented with virtually no loss of time.

Repetitive activities are recorded and simply saved as patterns. With these patterns and, for example, several laser projectors, it is also possible to use teams working in parallel, thus increasing the throughput of steel trusses. SL Laser works for your profit.